Tactical Engineering Machines: A Comprehensive Guide to Purchasing

Introduction to Tactical Engineering Machines

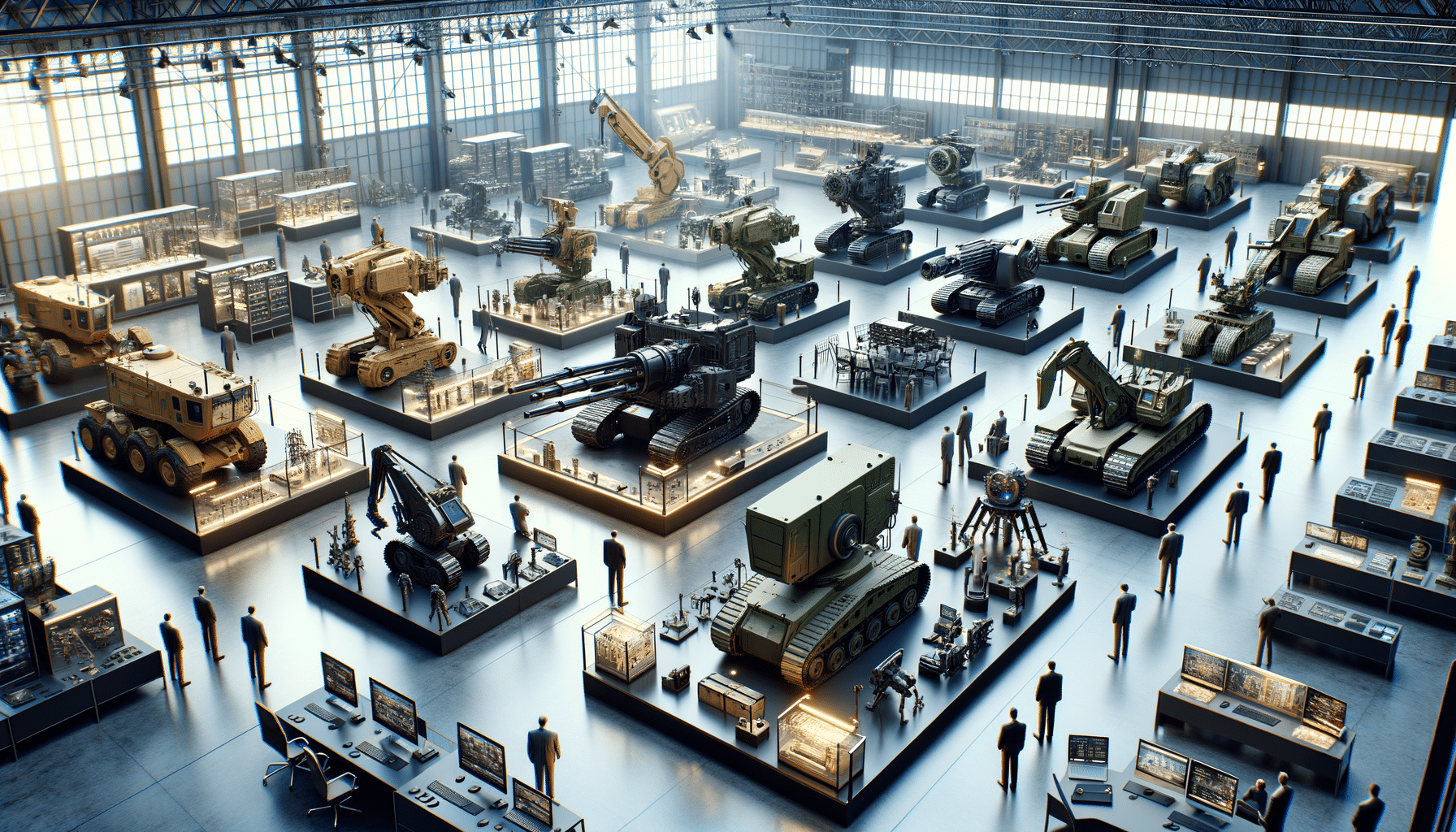

Tactical engineering machines are pivotal in various industries, providing essential support in construction, military operations, and emergency services. These machines are designed to perform complex tasks with precision and efficiency, making them indispensable tools for professionals. With the rapid advancements in technology, the market for these machines has grown, offering a wide array of options for potential buyers.

Understanding the significance of tactical engineering machines involves recognizing their role in enhancing productivity and safety. Whether it’s a construction site requiring heavy-duty equipment or a military operation needing specialized machinery, these machines are engineered to meet the highest standards of performance. This article delves into the different types of tactical engineering machines available for sale, providing insights into their features, benefits, and considerations for purchase.

Types of Tactical Engineering Machines

The market for tactical engineering machines is diverse, catering to various needs and applications. Some of the most commonly sought-after machines include:

- Excavators: These machines are essential for digging and moving large quantities of earth. They are widely used in construction and mining industries for their versatility and power.

- Bulldozers: Known for their strength, bulldozers are used to clear land, push large quantities of soil, and level terrain. Their robust design makes them ideal for heavy-duty tasks.

- Cranes: Essential for lifting heavy materials, cranes are used in construction, shipping, and manufacturing industries. They come in various sizes and capacities, tailored to specific lifting needs.

- Military Vehicles: Designed for defense operations, these machines include armored vehicles and tactical transporters, providing mobility and protection in combat scenarios.

Each type of machine offers unique capabilities, and selecting the right one depends on the specific requirements of the task at hand. Buyers must consider factors such as the machine’s capacity, durability, and compatibility with existing equipment.

Key Features to Consider

When purchasing tactical engineering machines, it is crucial to evaluate several key features to ensure optimal performance and value for investment. These include:

- Durability: Machines should be constructed from high-quality materials to withstand harsh working conditions and prolonged use.

- Efficiency: Look for machines that offer fuel efficiency and low operational costs without compromising on performance.

- Technology Integration: Modern machines often come equipped with advanced technology, such as GPS systems and automation, to enhance precision and ease of operation.

- Maintenance and Support: Consider the availability of maintenance services and spare parts to ensure long-term operability.

By focusing on these features, buyers can make informed decisions that align with their operational needs and budget constraints.

Market Trends and Innovations

The tactical engineering machine industry is continuously evolving, driven by technological advancements and changing market demands. Recent trends include the integration of artificial intelligence and machine learning, which enhance machine capabilities and efficiency. These innovations allow for predictive maintenance, reducing downtime and extending the lifespan of the machines.

Another significant trend is the shift towards eco-friendly machines that minimize environmental impact. Manufacturers are increasingly adopting sustainable practices in their production processes, offering machines that are both powerful and environmentally conscious.

Keeping abreast of these trends can help buyers anticipate future needs and invest in machines that offer long-term benefits.

Conclusion: Making the Right Choice

Purchasing tactical engineering machines is a significant investment that requires careful consideration of various factors. By understanding the types of machines available, evaluating key features, and staying informed about market trends, buyers can make decisions that enhance their operational efficiency and productivity.

Ultimately, the right machine can transform the way tasks are executed, offering improved safety, speed, and precision. As the industry continues to innovate, the options available to buyers will only expand, providing even more opportunities for growth and development.